What’s next?

Our goal: by 2026, 100% of Forclaz products will be eco-designed, according to the criteria defined by the Decathlon group. In 2021, we were at 32%: there’s still a long way to go and we’re putting all our energy into it.

To achieve this, we need to address many challenges and continue our explorations.

1 - RECYCLED RAW MATERIALS

Many Decathlon Group brands already offer products made from recycled materials: recycled polyester, cotton or plastic.

Among the many benefits of using recycled materials is that we do not have to draw on natural resources again. Also, it can allow us to work with materials that are already coloured, since recycling is based on sorting the fibres by colour. Also, using recycled yarns in this way avoids the dyeing stage.

It is another way of working with the material, with new challenges:

- How can the properties of the material be maintained when it is no longer virgin?

- How to source sufficient quantities of materials that are difficult to recycle?

For example, today we know how to recycle polyamide when it comes from production offcuts (limited quantities) but we have not yet identified a sector for recycling polyamide from donations or waste from individuals.

2 - ALTERNATIVE DYEING

The management of smaller volumes, especially for small series of products, is a real challenge for us. Indeed, the dope dyed can only be applied from a certain quantity: if our need for coloured yarns is below this threshold, we have to use conventional dyeing processes.

Fortunately, more responsible dyeing solutions are emerging, and we are always willing to experiment with them:

- In particular, we are studying the Clean dyed process, also known as supercritical CO2 dyed: a closed loop process where CO2 will be concentrated at very high pressure to act as a solvent. No soaking is necessary: the dye will impregnate deeply into the threads. This is a promising alternative that would allow us to significantly reduce the impact of dyeing. However, this technique is only applicable to polyester.

- We are also beginning to explore plant dye solutions, which would be created from plant residues already used by the industry. If this project is successful, we could use it to dye our virgin wools, for example.

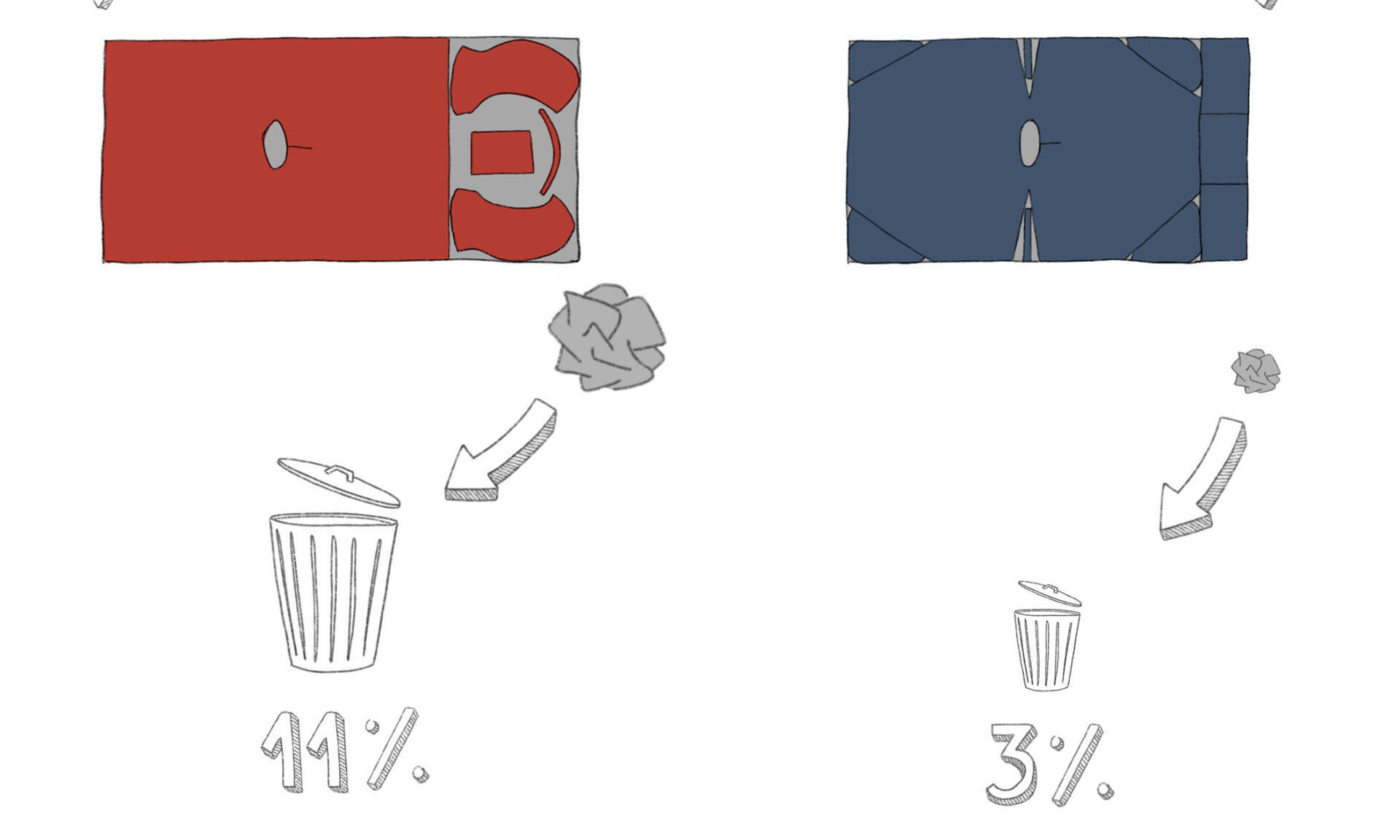

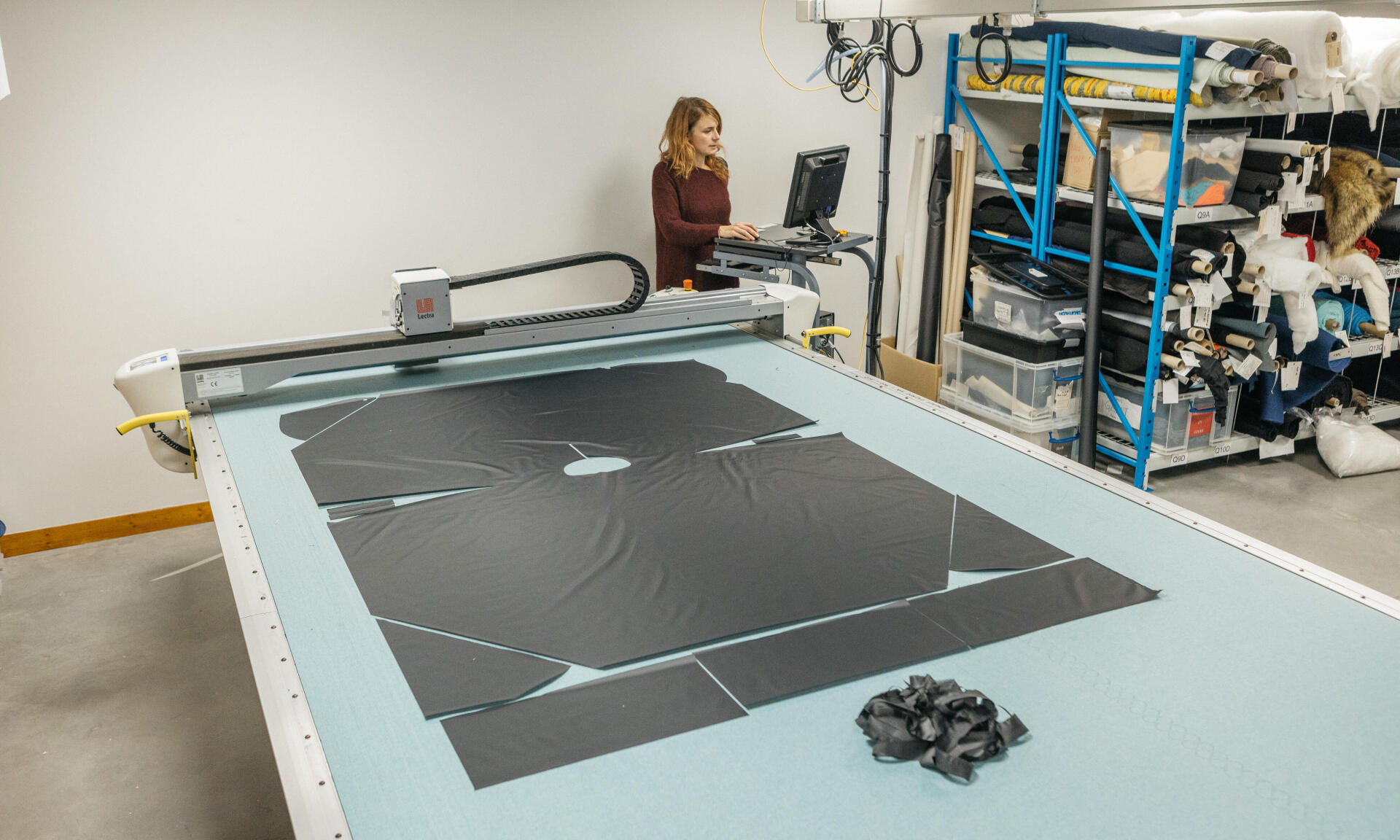

3 - FROM MINIMAL WASTE TO MINIMAL ASSEMBLY

Minimal waste design has been a core strategy at Decathlon for several years. Also, for some products, material consumption is already optimised to the maximum.

We continue to develop new products with minimal waste design where technically possible.

At the same time, we are working on a minimal assembly project, which consists of limiting the number of seams during the assembly of a product.

This work can only be carried out if the supplier's production tool is well known: depending on the assembly technology it uses, we will look for suitable solutions. For example, we are working on a heat-welded jacket, i.e. the seams are not stitched like conventional seams but press-welded. That way, there are almost no seams. On this jacket, there are two hand pockets and in order to optimise handling, the hem of the bottom of the jacket is used as the bottom pocket. This is all the more interesting as the jacket is more resistant: the pockets will not develop holes.

In this way, we reduce the human time spent on the product and therefore its final cost... which gives us a better chance of bringing production back to Europe. On the other hand, this process consumes a little more material than a traditional jacket, so it is a compromise.